Energy Technologies Inc. | Model 500 Nuclear Belt Scale /Density Meter

Nuclear Belt Scale /Density Meter - Model 500

Overview

The Model 500 Nuclear Belt Scale /Density Meter is a state-of-the-art device that uses gamma radiation to measure the weight of bulk materials on conveyor belts—accurately and without contact.

How It Works

The scale operates on the principle of gamma energy attenuation, which varies with material density. A sealed radioactive source and detector are mounted across the conveyor. The radiation passes through the material and is measured below the belt. An industrial computer processes these signals and displays real-time weight data.

Key Benefits

- • Non-contact: No mechanical components touch the belt or material.

- • High precision: +/- 0.5% accuracy, unaffected by belt speed or load.

- • Consistency: Variations in belt loading and belt speed do not affect the measurements

- • Low maintenance: No moving parts—no wear, no breakage.

- • Frequent updates: Delivers averaged weight data every minute.

- • Easy installation: Mounts to existing conveyor with no modifications required.

Integration

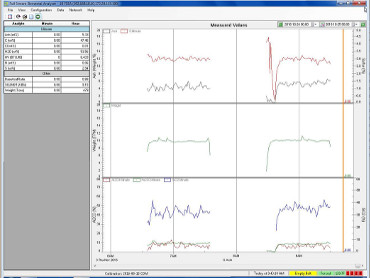

Readings are taken every 3 seconds and averaged over 60 seconds. Output is available via analog connections or direct database access for seamless integration into plant control systems.

Coal Application

ETI DataView

Return to Products

Return to Products Datasheet

Datasheet